Contact Information

Telephone:+86 0374-6818007

Mobile:+86 18567333000

Mobile:+86 13623748797

Mobile:+86 13953647099

E-mail:xuchangruiteng@126.com

Address: Changge Economic Development Zone, Henan, China

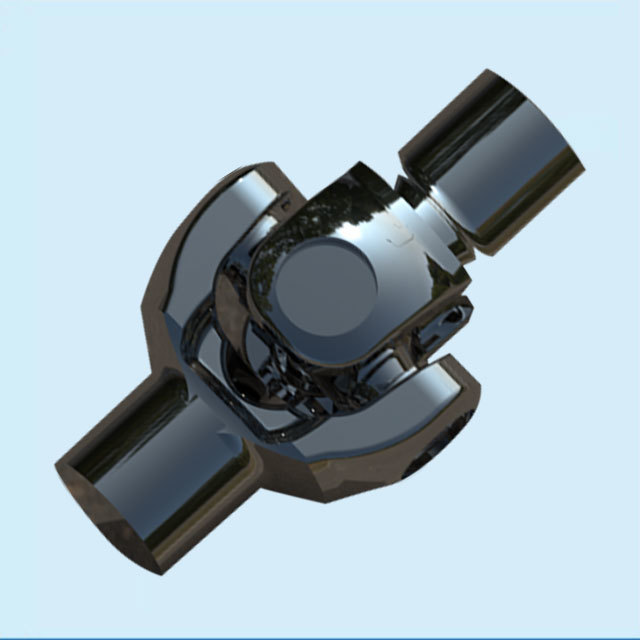

RT-ZC2050-01

The steering knuckle assembly is a critical component in a vehicle's suspension and steering system, designed to ensure smooth directional control and stability. Built for durability and precision, the steering knuckle assembly connects the wheel hub to the suspension and provides the pivotal axis that allows the front wheels to turn efficiently. It supports both the vertical load of the vehicle and the dynamic forces from braking and turning, making it essential for safety and performance.

Crafted from high-strength materials such as forged steel or cast iron, the steering knuckle assembly is engineered to withstand heavy loads, harsh road conditions, and long-term wear. Its precise construction ensures proper wheel alignment and seamless integration with other suspension parts like control arms, tie rods, and ball joints. By maintaining accurate geometry, it contributes to better handling, reduced tire wear, and a comfortable ride.

The steering knuckle assembly also plays a key role in housing the wheel hub and bearing, which are vital for rotation and load support. It is commonly used in both front and rear suspensions across a wide range of vehicle types, including passenger cars, trucks, SUVs, and commercial vehicles. For vehicles with disc brakes, the knuckle also provides the mounting point for the caliper, making it essential for reliable braking performance.

The components of the drive axle are the main reducer, differential, wheel transmission device, and drive axle housing. The drive axle is a mechanism located at the end of the transmission system that can change the speed and torque from the gearbox and transmit them to the drive wheels. The function of the drive axle is to:

1. The engine torque transmitted from the universal transmission device is transmitted to the driving wheels through the main reducer, differential, half shaft, etc., to achieve deceleration and increase torque;;

2. Changing the direction of torque transmission through the main reducer bevel gear pair;

3. By using a differential, the differential effect between the two wheels is achieved, ensuring that the inner and outer wheels turn at different speeds;

4. Load bearing and torque transmission are achieved through the axle housing and wheels.

Xuchang Ruiteng Machinery Manufacturing Co., Ltd. has advanced forging, processing, and testing equipment, as well as a group of professional technical research and development talents and a lean management team. It is a professional enterprise that manufactures front drive axles and components for military, civilian vehicles, engineering machinery, agricultural machinery, and other industries.

Key words:

RT-ZC2050-01

ADVANTAGE

Why choose us

Technical Team

Has advanced forging, processing, testing equipment, as well as a group of professional technical research and development personnel and capable management team

Quality System

Establish a quality assurance system of "management, technology and service", adopt excellent technology, and strictly control product quality

Sales Network

The company's sales network has covered the domestic and Southeast Asia, Europe and other countries and regions

After-sales service

Adhering to the "all meet customer needs" business philosophy; high-quality products, reasonable prices, perfect service, integrity of cooperation is our business purpose

Note: Please leave your contact information and our professionals will contact you as soon as possible!