product

Recommend Products

About Ruiteng Machinery

Equip Ourselves and Serve Our Customers with Advanced Equipment and Quality Services

SINCE 2017

Xuchang Ruiteng Machinery Manufacturing Co., Ltd

Market-oriented, research-driven, and innovation-based, we are dedicated to expanding both domestic and international markets with the utmost care and effort.

Xuchang Ruiteng Machinery Manufacturing Co., Ltd. was founded in 2017 and is situated in the Changge Economic and Technological Development Zone, Henan Province, where it is adjacent to the Beijing-Guangzhou Railway and Beijing-Zhuhai Expressway and only 20 kilometers away from Zhengzhou Xinzheng International Airport, so it enjoys a prime geographical position.

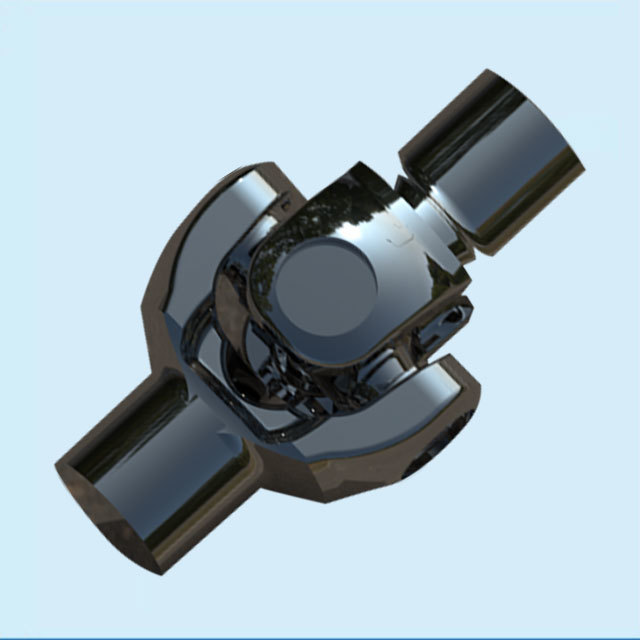

Our company boasts advanced forging, machining, and testing equipment, as well as a team of professional technical R&D talents and capable management personnel. We specialize in the production of front drive axles and components for military and civilian vehicles, construction machinery, agricultural machinery, and other applications.Currently, our major equipment partners include FAW Jiefang, Qingte Axle, Shandong Heavy Industry Group, LGMG, and Foton Lovol, among others. We also manufacture a comprehensive range of front-drive axle components for various vehicles, including but not limited to all front-drive axle components for EQ240 (2.5 T), EQ245 (3.5 T), 2060, 2080, 2100, Sinotruk 2190, Beiben Trucks, BJ130, Isuzu, Nanjing 131, and Jiefang 30, including construction machinery axles, three-pivot universal joint front-drive axles, single-cross universal joint front-drive axles, double-cross universal joint front-drive axles, outer halfshafts, left and right halfshafts, five-ball halfshafts, halfshaft connectors, cross-pin shells, double-axle universal joints, three-pivot universal joints, three-pivot bearing assemblies, left and right steering knuckle housings, main-shaft bearing pedestals, front axle hub spindles, wing bearings, outer halfshaft flanges, etc. Our independently developed 240, 245, and new-type halfshafts (which replace the three-pivot universal joint with a cross universal joint) have gained widespread recognition and favor from customers since their launch.

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

Here is the placeholder text

ADVANTAGE

Why choose us

Technical Team

We boast advanced forging, machining, and testing equipment, as well as a team of professional technical R&D talents and capable management personnel.

Quality System

Establish a quality assurance system integrating “management, technology, and service”, adopt excellent technologies, and strictly control quality.

Selling Network

Our sales network has extended to all Chinese markets as well as countries and regions in Southeast Asia, Europe, and so forth.

After-Sales Service

We adhere to the business philosophy of “fulfilling all customer needs comprehensively”, and high-quality products, reasonable prices, impeccable services, and sincere cooperation are our business purposes

Blog

2025-07-12

The Essential Guide to Choosing the Best Offside Drive Shaft for Your Vehicle

2025-07-07

Expert Tips for Choosing the Right Front Drive Axle Halfshaft Assembly

2025-07-02

Understanding Classy 8.8 Axle Tubes: Key Insights for Automotive Professionals

2025-06-27

Halfshafts Explained: Why Fancy Single Halfshafts Are a Game Changer